摘要:,,本文探讨了电气设备停止运作的英文表达及其原因分析与应对策略。当电气设备停运时,可能涉及多种因素如电源故障、设备老化、过载等。针对这些问题,文章提出了相应的分析和解决策略。通过检查电源、设备维护、负载管理等措施,可以有效预防和解决电气设备停运问题,确保设备的正常运行。

Summary: This article mainly explores the phenomenon of electrical equipment malfunction, analyzes its possible causes, and proposes corresponding countermeasures. The aim of this article is to help professionals quickly identify problems and take effective measures to ensure the normal operation of electrical equipment.

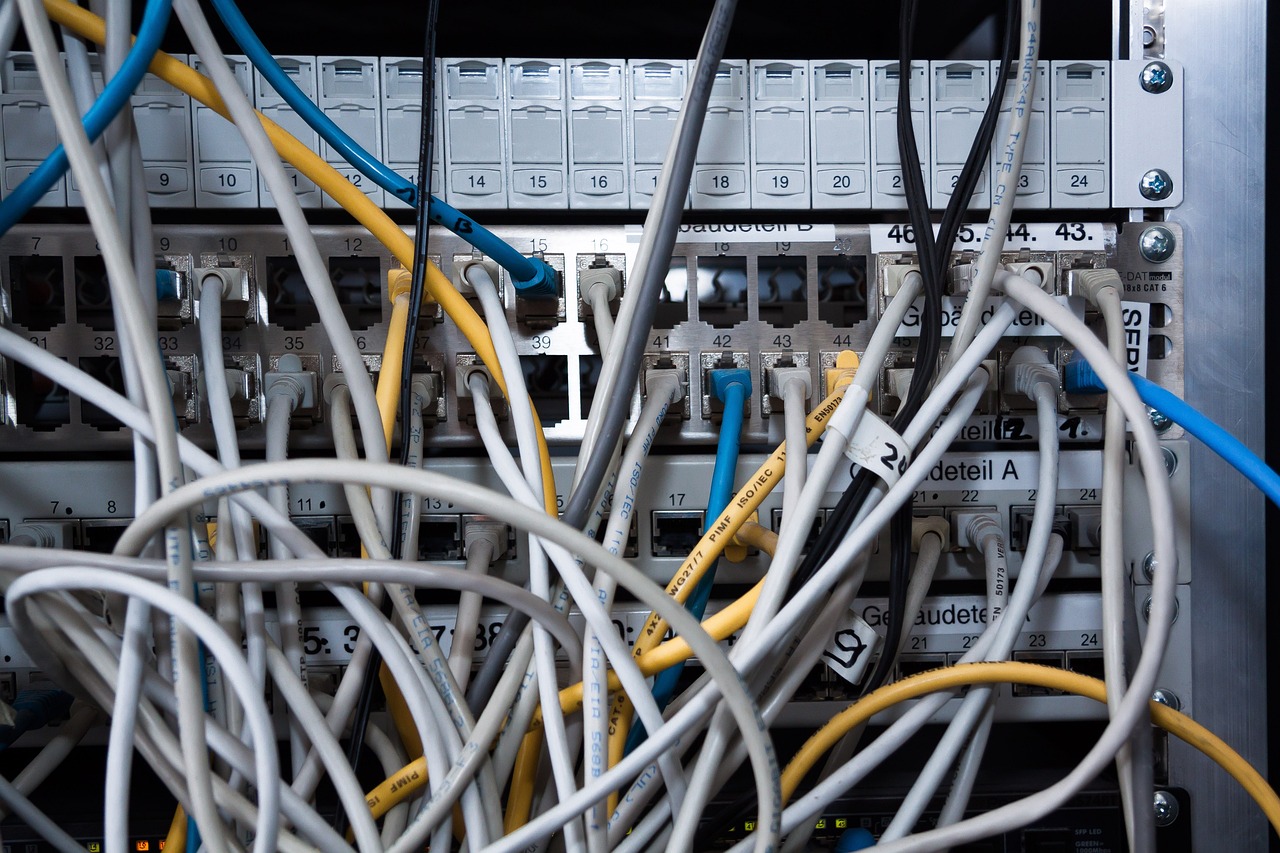

Electrical equipment plays a vital role in modern society, and its normal operation is crucial in various fields such as industry, commerce, and daily life. However, during operation, electrical equipment may suffer from malfunctions, which not only affect the normal use of the equipment but also cause losses to production and daily activities. This article will delve into the causes of electrical equipment malfunction and propose effective countermeasures.

H3. Electrical Equipment Failure Analysis

1、Overload: When the load on electrical equipment exceeds its rated value, it may cause the equipment to overheat and result in malfunction.

2、Power issues: Voltage instability, excessive current, or power interruption can all lead to electrical equipment malfunction.

3、Equipment aging: Long-term use of electrical equipment can lead to performance degradation due to component aging, wear, and tear.

4、Improper operation: Irregular operations, misuse, or overuse can damage electrical equipment and cause it to malfunction.

5、Environmental factors: High temperature, humidity, corrosion, etc., can affect the normal operation of electrical equipment and cause it to malfunction in severe cases.

H3. Countermeasures

1、Load management: Manage the load on electrical equipment reasonably to ensure it operates within its rated range. Regular maintenance and inspection should be carried out to ensure the equipment is in good condition.

2、Power quality monitoring: Establish a power quality monitoring system to monitor voltage, current, and other parameters in real-time. Take prompt measures when power quality issues arise to avoid damage to the equipment.

3、Equipment maintenance and management: Develop a maintenance plan for electrical equipment, conduct regular maintenance, and detect potential problems promptly. Replace or repair aging equipment to avoid malfunction due to aging.

4、Operator training: Provide professional training for operators of electrical equipment to improve their skill levels, regulate operational behavior, and reduce damage caused by misoperation.

5、Environmental control: Provide a good operating environment for electrical equipment, such as controlling indoor temperature and humidity, to reduce the impact of environmental factors on the equipment's operation. Take corresponding protective measures for equipment operating in harsh environments to ensure its normal operation.

H3. Case Analysis

In a factory, a critical electrical equipment suddenly malfunctioned during production. After examination, it was found that the equipment had been running for a long time, leading to internal component aging. Additionally, the load on the equipment had exceeded its rated value for a long time, causing it to overheat and malfunction. The factory took the following measures to address the issue: 1) repaired the equipment and replaced aging components; 2) adjusted the production process to reduce the load on the equipment; 3) conducted regular maintenance and inspection on the equipment. After implementing these measures, the equipment's operating status improved significantly, and production resumed normal operations.

Electrical equipment malfunctions are a common phenomenon, with causes that may involve overload, power issues, equipment aging, improper operation, and environmental factors. To ensure the normal operation of electrical equipment, effective countermeasures should be taken, including load management, power quality monitoring, equipment maintenance and management, operator training, and environmental control. Implementing these strategies can minimize electrical equipment malfunctions and ensure normal production and daily activities.

H3. Suggestions and Outlook

Suggestions:

a) Increase investment in electrical equipment maintenance to improve reliability and stability;

b) Establish a comprehensive equipment management system to ensure normal equipment operation;

c) Strengthen cooperation with suppliers to obtain timely technical support and component replacement.

Outlook: With the continuous development of technology, the technical level of electrical equipment will continue to improve. The degree of intelligence and automation of equipment will further increase. Electrical equipment will become more reliable, efficient, and energy-saving. With the application of the Internet of Things and big data technology, remote monitoring and fault diagnosis of electrical equipment will become possible, which will further improve the efficiency and reliability of equipment operation. Through continuous technological and management innovation, we will be better able to solve the problem of electrical equipment malfunctioning and provide better support for production and daily life.(电气设备停止运作英文翻译改为Electrical Equipment Failure Analysis)

转载请注明来自河南中豫电气设备有限公司,本文标题:《电气设备停止运作的原因分析及应对策略,故障解析与解决之道》

豫ICP备19039067号-1

豫ICP备19039067号-1

还没有评论,来说两句吧...